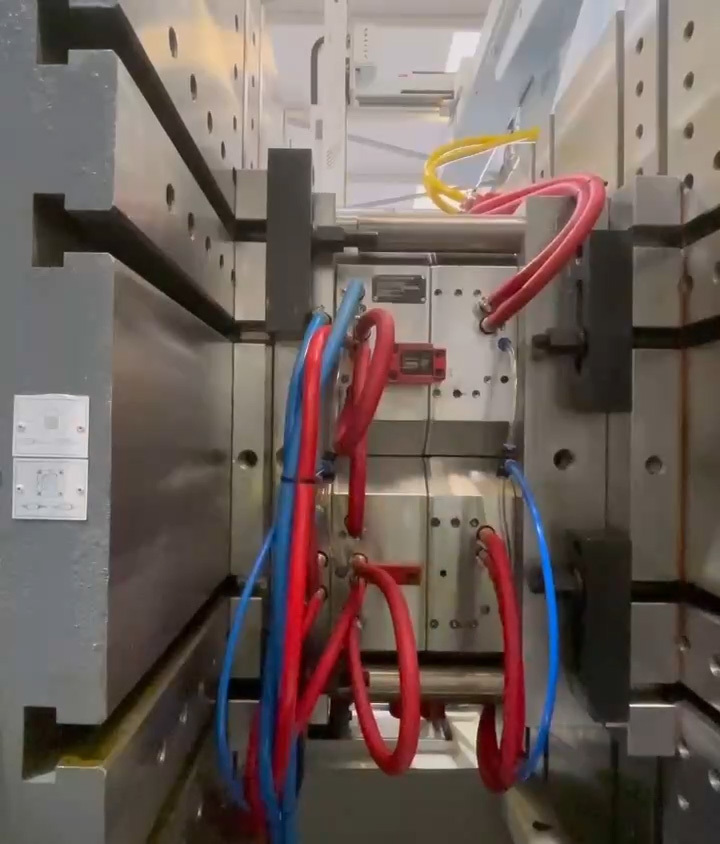

Customized Moulding Division

Need to figure out your mold-cooling energy requirements for the various polymers you run

A Perfect Injection Moulding Solution

Material

A homogenous melt is required for consistent part quality, but achieving it requires balancing a number of factors, including barrel usage and temperature as well as screw speed, backpressure and residence time. Learn how to prepare your melt for molding success in this two-part series

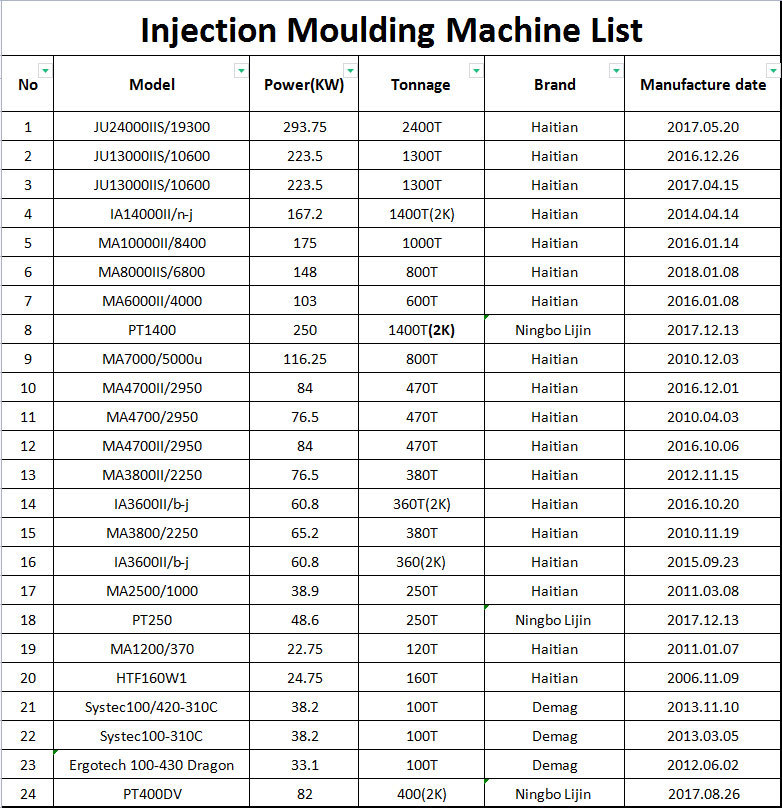

Injection molding equipment

During the injection molding process, the plastic that is injected into the mold must be molten, homogeneous and of a required melt density. This preparation of the melt happens in the molding barrel with the help of heater bands and the action of the screw.

Part of Work Site