Packaging Parts Mould

For consumer goods, closures, medical devices or for automotive componnets, the variety of possible applications of plastic packaging products is widely growing.

Four areas of packaging

undefined

Advanced Machining Capabilities

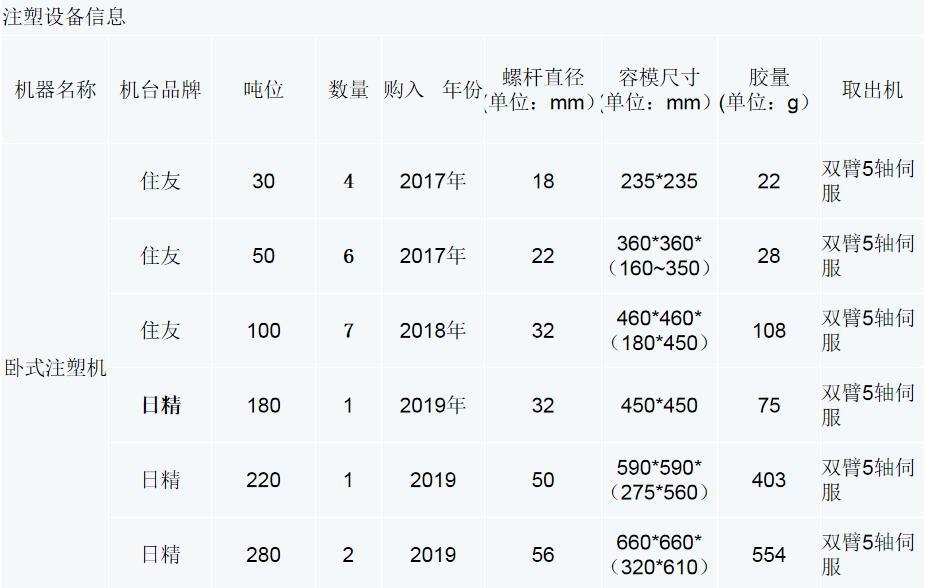

Using the latest in technological equipment (EDM, multi axis CNC, and plastic injection molding machines), we are able to produce molds with high quality and tight tolerance from simple to sophisticated design.

Facility List

Inspection & Quality Control

JVP always uses a 3D measuring machine to inspect the electrode before EDM, and we always inspect the cavity/core & slider before mold trial.

Zeiss Spectrum

FARO platinum measurement arms(3m)

Zeiss MMZ E

FARO platinum measurement arms(3m)

Flaw Detector

Hardness Tester

Zoller Tool Auto- measuring Machine

PARTNER

JVP technical consultants at your service!

Leave a message